News

Market Analysis for Light Conveyor Belt At Home and Abroad

发布时间 : 2018-10-20 浏览次数 : 次

With the rapid development of China's economy, industrial automation has gradually replaced labor, and production efficiency has continued to increase. As one of the necessary accessories for automation, light conveyor belts play an important role and are widely used in food, textile, printing, medicine, automobile manufacturing, packaging, building materials, chemical and other fields.

According to the authoritative statistics, in 2012, the market demand for light conveyor belts in China was 13 million square meters, and the market scale reached 1.6 billion RMB. In 2015, the market demand reached 16.5 million square kilometers, and the market scale was 2 billion RMB; The market demand reached 20.51 million square meters, and the domestic market scale was 2.8 billion RMB. The demand for light conveyor belts will increase year by year in the next few years, and will grow at a rate of 10-20% per year. The domestic market will exceed 4 billion RMB .

Globally, with the economic development, the overall market size of the conveyor belt industry has maintained steady growth. According to the authoritative statistics, in 2017, the global conveyor belt market is about 600-700 million square meters per year, and on it is mainly heavy-duty conveyor belts, accounting for 75%-85% of the conveyor belt market, and the proportion of light conveyor belts is only 15%-25%.

However, in Europe, the United States, Japan and other countries and regions, owing to the high automation, light conveyor belts have been widely used in food processing, logistics and transportation, agricultural products processing, stone processing, recreation and fitness, tobacco production, wood processing, textile printing and dyeing, electronics, manufacturing, printing and packaging industries.

In China, the application of light conveyor belt started late. In recent years, light conveyor belts have been applied. A large number of enterprises still use canvas or rubber conveyor belts. The products are heavy, energy-consuming and do not meet the requirements of environmental protection and hygiene.

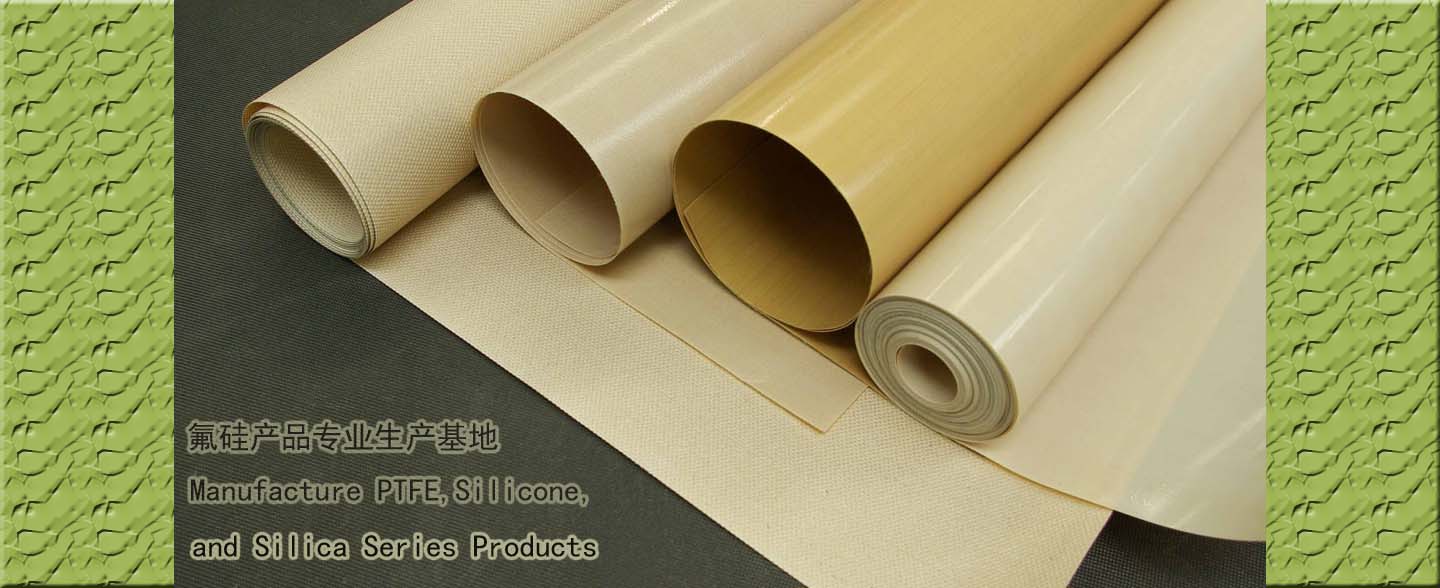

Since 2008, with the continuous introduction of foreign advanced production methods and the rapid development of polymer materials technology in China, we have developed light conveyor belts of various performances, which not only meet the needs of domestic downstream industries, but also gradually open up high-ends in Europe and America. The market, by virtue of its superior cost performance, has gradually gained a place. Taking PTFE conveyor belt as an example, we have been able to stably produce high-quality PTFE mesh conveyor belt, PTFE coated fiberglass conveyor belt, PTFE Kevlar fabric conveyor belt, anti-static PTFE conveyor belt and etc. 80% of the US demanding companies have been importing them from China. With the further expansion of China's globalization, trading business for China's conveyor belt has expanded to South America, Middle East countries, South Africa, and other new economy.

Nowadays, light conveyor belts have become more and more recognized by foreign high-end markets as “Made in China” moves toward “China's quality”. Despite the wide variety of manufacturers in the conveyor belt industry and the uneven quality, the factories targeted at the mid-to-high end have never stopped researching the market and developing products. Taking the PTFE conveyor belt industry as an example, although our company entered the market late, our company has not only established a stable supply system, but also developed a certain independent research system by introducing advanced foreign production equipment and relying on domestic polymer technicians. Some high-end products, such as PTFE double-sided tape, silicone coated fiberglass tape, four fluorine fiberglass fabric, puffing fiberglass fabric, high silica fiberglass fabric and etc.

PTFE Mesh Conveyor Belt PTFE Coated Fiberglass Conveyor Belt

Light conveyor belts will continue to replace the market share of heavy-duty conveyor belts with its advantages of environmental protection, low carbon consumption, low energy consumption, light weight and convenience, and more widely applied in the industrial production and life fields.

According to the authoritative statistics, in 2012, the market demand for light conveyor belts in China was 13 million square meters, and the market scale reached 1.6 billion RMB. In 2015, the market demand reached 16.5 million square kilometers, and the market scale was 2 billion RMB; The market demand reached 20.51 million square meters, and the domestic market scale was 2.8 billion RMB. The demand for light conveyor belts will increase year by year in the next few years, and will grow at a rate of 10-20% per year. The domestic market will exceed 4 billion RMB .

Globally, with the economic development, the overall market size of the conveyor belt industry has maintained steady growth. According to the authoritative statistics, in 2017, the global conveyor belt market is about 600-700 million square meters per year, and on it is mainly heavy-duty conveyor belts, accounting for 75%-85% of the conveyor belt market, and the proportion of light conveyor belts is only 15%-25%.

However, in Europe, the United States, Japan and other countries and regions, owing to the high automation, light conveyor belts have been widely used in food processing, logistics and transportation, agricultural products processing, stone processing, recreation and fitness, tobacco production, wood processing, textile printing and dyeing, electronics, manufacturing, printing and packaging industries.

In China, the application of light conveyor belt started late. In recent years, light conveyor belts have been applied. A large number of enterprises still use canvas or rubber conveyor belts. The products are heavy, energy-consuming and do not meet the requirements of environmental protection and hygiene.

Since 2008, with the continuous introduction of foreign advanced production methods and the rapid development of polymer materials technology in China, we have developed light conveyor belts of various performances, which not only meet the needs of domestic downstream industries, but also gradually open up high-ends in Europe and America. The market, by virtue of its superior cost performance, has gradually gained a place. Taking PTFE conveyor belt as an example, we have been able to stably produce high-quality PTFE mesh conveyor belt, PTFE coated fiberglass conveyor belt, PTFE Kevlar fabric conveyor belt, anti-static PTFE conveyor belt and etc. 80% of the US demanding companies have been importing them from China. With the further expansion of China's globalization, trading business for China's conveyor belt has expanded to South America, Middle East countries, South Africa, and other new economy.

Nowadays, light conveyor belts have become more and more recognized by foreign high-end markets as “Made in China” moves toward “China's quality”. Despite the wide variety of manufacturers in the conveyor belt industry and the uneven quality, the factories targeted at the mid-to-high end have never stopped researching the market and developing products. Taking the PTFE conveyor belt industry as an example, although our company entered the market late, our company has not only established a stable supply system, but also developed a certain independent research system by introducing advanced foreign production equipment and relying on domestic polymer technicians. Some high-end products, such as PTFE double-sided tape, silicone coated fiberglass tape, four fluorine fiberglass fabric, puffing fiberglass fabric, high silica fiberglass fabric and etc.

PTFE Mesh Conveyor Belt PTFE Coated Fiberglass Conveyor Belt

Light conveyor belts will continue to replace the market share of heavy-duty conveyor belts with its advantages of environmental protection, low carbon consumption, low energy consumption, light weight and convenience, and more widely applied in the industrial production and life fields.